Very soon – on January 14, 2027 -the Regulation (EU) 2023/1230 of the European Parliament and of the Council on machinery, which repeals the Machinery Directive 2006/42/EC, will become fully binding.

Why do we call a date a year and a half away “soon”? First of all, time seems to fly lately. Second of all, this regulation was published over two years ago, and this might be the first time you’re hearing about it- especially considering that even after 15 years of the Machinery Directive being in force, many manufacturers still do not fully comply with it.

This post kicks off a series that will introduce readers to the new requirements imposed by EU law for placing new products – machines and related items – on the market (and, in some cases, for internal company use).

Why has the directive been replaced by a new machinery regulation?

Without going into too much detail: a regulation, unlike a directive, does not need to be transposed into national law and is directly applicable across the entire EU. This ensures greater effectiveness and uniform application. Is better the enemy of good? Not necessarily. The Directive had many gaps – it did not account for machines using neural networks, adaptability, or operation in unstructured environments. The new regulation is an evolution of a more flexible and technologically advanced safety assurance system instead of the traditional regulatory approach.

To put it simply: a traditional rail trolley with a classic control system, when derailed, poses a predictable, local threat. On the other hand, a tracked vehicle with a vision system and AI control that leaves its original work environment and deviates from its designer’s intended purpose could start acting like a seventh Terminator sequel. Technological progress – especially in AI-forces us to choose between becoming a safety-focused museum or responsibly embracing automation. To enable safe progress, the Commission has introduced new definitions and conformity assessment procedures.

To help us navigate future topics, let’s clarify a few basics. Before placing a product on the market, Decision No. 768/2008/EC – through other legislation – indirectly requires a conformity assessment. This is a process to confirm that a product meets legal requirements, especially those laid out in EU directives and regulations (e.g., machinery, low voltage, EMC). The result of this assessment forms the basis for issuing an EU Declaration of Conformity (or EC DoC) and affixing the CE mark.

The Machinery Directive had some inconsistencies with Decision 768/2008/EC, which have been addressed in the new regulation. This unification and simplification, ultimately leading to fewer overlapping laws comes at a cost: the invalidation of harmonized standards. This means that all harmonized standards related to the Machinery Directive will formally become outdated and will require re-issuance, at minimum with confirmation from standardization committees of their compliance with the new regulation. That is, if they still comply at all, as the new regulation introduces several changes.

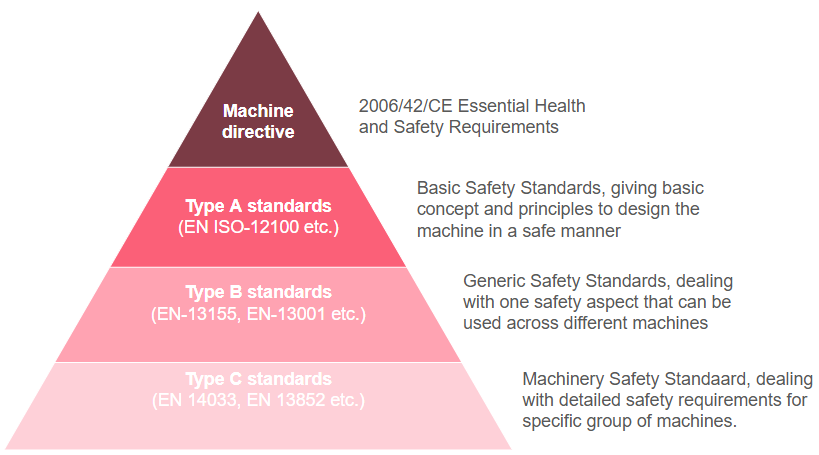

To better understand what the regulation introduces, let’s briefly outline the current requirements. So far, safety aspects of most machines have been described in a general manner in the Machinery Directive. The Low Voltage Directive (LVD) requirements regarding machine power supply were included within it. Since these requirements are written in a fairly general, legalistic language, harmonized standards are used for design purposes.

This approach greatly simplifies matters. For example, the standard EN 60204-1-Electrical Equipment of Machines is harmonized with both the Machinery Directive and LVD and includes detailed safety requirements for voltage, grounding, protection against electric shock, emergency stops, wiring, connectors, control panels, etc. It gives a clear design framework for a machine’s electrical system.

For machines of average complexity using commonly known solutions, harmonized standard EN ISO 12100-General Principles for the Design of Safe Machinery, explains how to design machines that meet the Machinery Directive’s requirements. If these two standards are followed thoroughly, there is often no need to refer directly to the Directive unless unusual questions arise. If they do, other harmonized standards likely cover them. Harmonized standards are not mandatory, but they are extremely helpful and offer a presumption of conformity with the directive.

When notified body is required?

The situation is different for particularly dangerous machines, listed in Annex IV of Directive 2006/42/EC. These include items like saws, presses, injection molding machines, and car lifts. We encourage you to review the full list, these are just a few examples. For these machines, one might say that harmonized standards are effectively mandatory, because if they are not met, a self-declared conformity statement is not sufficient. Instead, a notified body must be involved in the conformity assessment.

This answers a frequent question from designers who haven’t conducted the full market placement process for an Annex IV machine. A notified body examination is not required, if harmonized standards are fully met. For example, when designing a press, if all requirements of the harmonized standard PN-EN 12622+A1:2014-02 are fulfilled, there is no need for further testing with a notified body.

Of course, there are exceptions. Some Annex IV machines fall under the authority of the Local Office of Technical Inspection (in Poland – UDT), which acts as a special type of notified body. Some devices, even though they fall under the Machinery Directive and require conformity assessment and CE marking, must also be approved by the UDT before being put into service in Poland. These devices often fall under other directives too. Examples include: pressure equipment (e.g., steam boilers, pressure tanks, pipelines),on-pressure devices (e.g., tanks for storing flammable or corrosive liquids), lifting and handling equipment (e.g., cranes, hoists, mobile platforms, winches), fuel vapor recovery systems.

This is often where the manufacturer’s responsibility ends, and the user’s responsibility begins. Before operating a UDT-regulated device, it must be registered with UDT and receive approval for use. This means that a properly designed machine, with complete documentation provided by the manufacturer, must still be registered by the end user. An example could be a machine with a winch whose parameters bring it under UDT supervision.

The UDT performs technical inspections, verifies documentation, checks the device’s condition, and ensures proper labeling (including the CE mark).

In future posts, we’ll explore in more detail the conformity assessment procedures under the current Machinery Directive and the new Regulation (EU) 2023/1230.

Leave a Reply